Contents

- 1 How to Make MC4 Solar Connectors

- 2 Understanding MC4 Connectors

- 3 Tools and Materials Required

- 4 Step-by-Step Guide on Making MC4 Solar Connectors

- 5 Tips for Ensuring Reliable Connections

- 6 Common Mistakes to Avoid

- 7 Testing and Quality Assurance

- 8 Maintenance and Care Tips

- 9 Advantages of DIY MC4 Connectors

- 10 Safety Precautions

- 11 Environmental Impact

- 12 Future Trends in MC4 Connector Technology

- 13 Applications of MC4 Connectors

- 14 Case Studies and Success Stories

- 15 FAQs

How to Make MC4 Solar Connectors

Welcome to our comprehensive guide on how to make MC4 solar connectors. As renewable energy continues to gain traction, more individuals are turning to solar power solutions for their homes and businesses. MC4 connectors play a crucial role in solar panel installations, providing a secure and reliable means of connecting solar modules. In this article, we’ll walk you through the process of making MC4 solar connectors, ensuring that you have the knowledge and skills to complete your solar projects successfully.

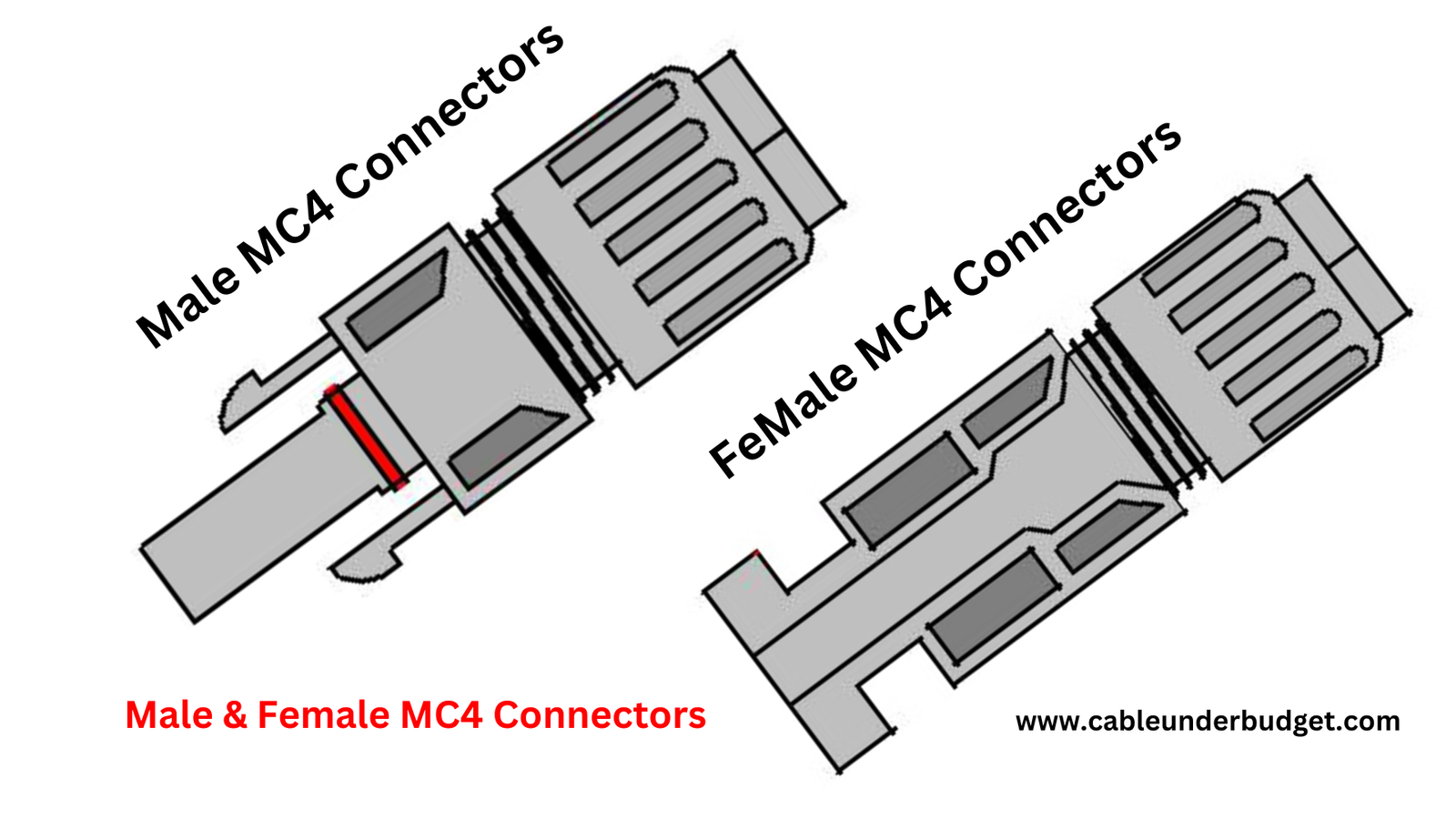

Understanding MC4 Connectors

MC4 connectors are industry-standard components used to connect solar panels, inverters, and other electrical components in photovoltaic systems. They consist of male and female connectors with a snap-lock mechanism, ensuring secure and weatherproof connections. Understanding the components and types of MC4 connectors is fundamental before diving into the assembly process.

Key Components of MC4 Connectors

-

- Male Connector: This component features a metal pin surrounded by a rubber insulator.

-

- Female Connector: The female connector consists of a metal socket enclosed in a rubber insulator.

-

- Locking Mechanism: MC4 connectors utilize a snap-in locking mechanism to secure the connection between male and female components.

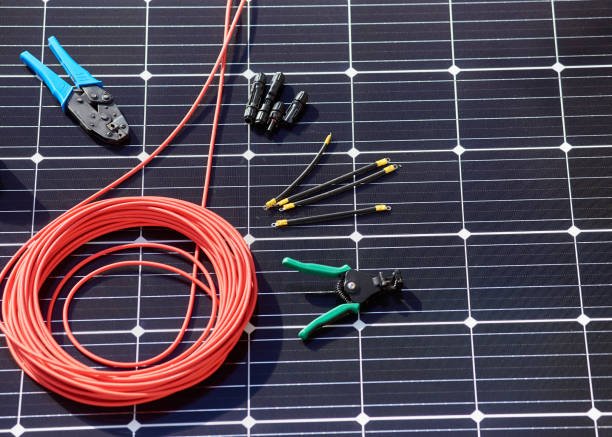

Tools and Materials Required

Before you begin making MC4 solar connectors, gather the following tools and materials:

-

- MC4 Connectors (Male and Female)

-

- Crimping Tool

-

- Wire Strippers

-

- Heat Gun

-

- Soldering Iron (optional)

-

- Electrical Tape

-

- Wire Cutters

Step-by-Step Guide on Making MC4 Solar Connectors

Now that you’re familiar with the basics, let’s dive into the process of making MC4 solar connectors.

1. Prepare the Cables

Start by stripping off the insulation from the ends of the solar cables to expose the conductive wires.

Insulation Stripping Techniques

-

- Using Wire Strippers: Carefully strip off the insulation using wire strippers, ensuring not to damage the underlying wires.

-

- Manual Stripping: If you don’t have wire strippers, you can carefully use a utility knife to remove the insulation.

2. Crimping the Connectors

Next, take the stripped ends of the cables and insert them into the appropriate crimping barrels of the MC4 connectors.

Proper Crimping Technique

-

- Positioning: Ensure that the wires are inserted fully into the crimping barrels, with no exposed conductors.

-

- Crimping Tool: Use a high-quality crimping tool to compress the barrels securely around the wires.

3. Applying Heat Shrink Tubing

After crimping, slide heat shrink tubing over the crimped area and use a heat gun to shrink the tubing, providing additional insulation and protection against environmental factors.

Tips for Ensuring Reliable Connections

Making MC4 solar connectors requires precision and attention to detail. Here are some additional tips to ensure reliable connections:

1. Double-Check Polarity

Before connecting the MC4 connectors, double-check the polarity to ensure that the positive and negative terminals align correctly.

2. Use Waterproofing Techniques

Apply waterproofing techniques such as silicone sealant or waterproof tape to the connections to prevent moisture ingress and corrosion.

Common Mistakes to Avoid

While making MC4 connectors, avoid common mistakes such as incorrect wire stripping, poor crimping technique, and over-tightening or under-tightening connectors. These mistakes can lead to inefficient connections and potential hazards in your solar system.

Testing and Quality Assurance

After making the connections, it’s crucial to test them for continuity and insulation resistance. Various testing methods, including visual inspection and electrical testing, can help ensure the reliability of MC4 connectors in your solar setup.

Maintenance and Care Tips

To prolong the lifespan of MC4 connectors, perform regular inspections, clean them periodically, and follow manufacturer guidelines for replacement. Proper maintenance ensures optimal performance and safety of your solar system.

Advantages of DIY MC4 Connectors

Making MC4 connectors yourself offers several advantages, including cost-effectiveness, customization options, and a valuable learning experience. DIY connectors empower you to tailor your solar system to your specific needs and gain hands-on skills in renewable energy technology.

Safety Precautions

When working with electricity, always prioritize safety. Wear appropriate safety gear, such as gloves and safety glasses, and follow safety protocols to prevent accidents and injuries during the assembly process.

Environmental Impact

The use of MC4 connectors contributes to the sustainability of solar energy by enabling efficient and reliable connections in photovoltaic systems. Additionally, many MC4 connectors are recyclable, further reducing their environmental footprint.

Future Trends in MC4 Connector Technology

As solar technology continues to advance, so do MC4 connectors. Future trends may include advancements in connector design, such as enhanced durability, efficiency, and integration with smart technology for monitoring and control.

Applications of MC4 Connectors

MC4 connectors find applications in various solar installations, including residential, commercial, and industrial projects. Their versatility and reliability make them indispensable components in the transition to clean and renewable energy sources.

Case Studies and Success Stories

Real-life examples of MC4 connector usage demonstrate their effectiveness and benefits. Whether it’s a small-scale residential installation or a large-scale solar farm, MC4 connectors play a vital role in harnessing solar energy efficiently and sustainably.