Contents

- 1 N-Type vs P-Type Solar Cell

- 2 Solar Cell Structure

- 3 Understanding the Operation

- 4 Comparing Efficiency and Performance

- 5 Manufacturing Considerations

- 6 Applications of N-Type and P-type solar cell

- 7 Future Perspectives and Innovations

- 8 Choosing the Right Solar Cell for Your Needs

- 9 Conclusion

- 10 FAQs

- 10.1 Which type of solar cell, N-type or P-type, is better for residential use?

- 10.2 Are N-type solar cells more suitable for commercial or industrial applications?

- 10.3 What factors should I consider when choosing between N-type and P-type solar cells?

- 10.4 Do N-type solar cells require special maintenance compared to P-type cells?

- 10.5 Are there any ongoing advancements in N-type and P-type solar cell technology?

N-Type vs P-Type Solar Cell

N-type and P-type solar cells are both made from silicon, a semiconductor material commonly used in solar panel manufacturing. The distinction between the two lies in the doping process, where certain impurities are intentionally added to alter the electrical properties of the silicon.

What are N-Type Solar Cells?

N-type solar cells are doped with elements like phosphorus, which introduces extra electrons into the silicon crystal structure. This excess of negatively charged electrons makes N-type cells abundant in negative charge carriers.

What are P-Type Solar Cells?

Conversely, P-type solar cells are doped with elements like boron, creating a deficit of electrons and resulting in an abundance of positively charged “holes” within the silicon lattice.

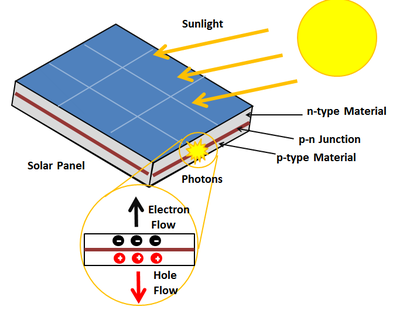

Solar Cell Structure

The structure of a solar cell typically consists of several layers, each playing a crucial role in converting sunlight into electricity. Here’s an overview of the typical structure of a solar cell:

-

- Top Contact/Grid: The top contact or grid is usually made of metal and serves as the positive terminal of the solar cell. It allows for the collection of current generated by the cell.

-

- Anti-Reflective Coating: A thin layer of anti-reflective coating is applied to the surface of the solar cell to minimize reflection of sunlight. This allows more light to penetrate into the cell, increasing its efficiency.

-

- Emitter: The emitter layer is doped with specific impurities to create an excess of electrons or “N-type” semiconductor material. This layer facilitates the movement of electrons when sunlight hits the cell.

-

- Base: The base layer is also doped with impurities to create a deficiency of electrons or “P-type” semiconductor material. This layer forms a junction with the emitter, creating an electric field that drives the flow of electrons.

-

- P-N Junction: The junction between the emitter and base layers forms a P-N junction, which is essential for the functioning of the solar cell. It allows for the separation of electron-hole pairs generated by sunlight, resulting in the generation of electrical current.

-

- Back Surface Field (BSF): The back surface field layer is designed to prevent the recombination of electrons and holes, thereby improving the efficiency of the solar cell.

-

- Back Contact: The back contact, typically made of metal, serves as the negative terminal of the solar cell. It allows for the collection of electrons generated by the cell.

-

- Substrate: The substrate provides structural support to the solar cell and is usually made of materials like silicon or glass. It also acts as a foundation for the various layers of the cell.

This layered structure allows solar cells to efficiently convert sunlight into electricity by harnessing the photovoltaic effect. As sunlight strikes the cell, it creates electron-hole pairs in the semiconductor material, generating an electric current that can be utilized for various applications.

Understanding the Operation

The operation of N-type and P-type solar cells revolves around the movement of charge carriers when exposed to sunlight.

N-Type Solar Cells Operation

When sunlight strikes an N-type solar cell, the excess electrons are excited, creating an electric current as these electrons move towards the positively charged region.

P-Type Solar Cells Operation

In P-type solar cells, sunlight generates electron-hole pairs, where electrons move towards the negatively charged region, leaving behind positively charged holes that contribute to the current flow.

Comparing Efficiency and Performance

One of the primary considerations when comparing N-type and P-type solar cells is their efficiency and performance characteristics.

Efficiency

N-type solar cells generally exhibit higher efficiency compared to P-type cells due to lower recombination rates and improved tolerance to impurities.

Performance in High-Temperature Conditions

N-type cells perform better in high-temperature conditions, thanks to their lower temperature coefficients, which reduce the impact of temperature variations on efficiency.

Manufacturing Considerations

Manufacturing processes play a significant role in determining the cost and feasibility of N-type and P-type solar cells.

Manufacturing Costs

P-type solar cells are typically more cost-effective to manufacture due to their simpler doping process and overall fabrication requirements.

Complexity

N-type solar cells, on the other hand, involve a more complex fabrication process, contributing to higher manufacturing costs but also offering advantages in terms of performance and durability.

Certainly! Here’s a chart outlining the manufacturing considerations for both N-type and P-type solar cells:

Applications of N-Type and P-type solar cell

Both N-type and P-type solar cells find applications across various sectors, each catering to specific needs and requirements.

N-Type Solar Cell Applications

N-type cells are preferred in applications where high efficiency and durability are paramount, such as residential and commercial installations.

P-Type Solar Cell Applications

P-type cells are commonly used in cost-sensitive projects or applications where slightly lower efficiency is acceptable, such as large-scale utility projects.

Certainly! Here’s a chart outlining the applications of N-type and P-type solar cells:

Future Perspectives and Innovations

Research and development efforts continue to focus on enhancing the efficiency, durability, and cost-effectiveness of both N-type and P-type solar cells. Innovations in materials science, manufacturing techniques, and cell designs are expected to drive further advancements in solar panel technology.

Choosing the Right Solar Cell for Your Needs

Selecting the ideal solar cell involves assessing priorities such as efficiency, durability, cost-effectiveness, and environmental conditions. N-type cells offer higher efficiency and durability, making them suitable for demanding applications, while P-type cells are more cost-effective and versatile. Evaluate your requirements, research manufacturers, and seek expert advice to make an informed decision aligned with your objectives.

Conclusion

In conclusion, the choice between N-type and P-type solar cells depends on various factors, including efficiency, cost, performance in different conditions, and specific application requirements. Understanding the differences between these two types enables informed decision-making and contributes to the continued growth of solar energy adoption worldwide.